Wednesday 15 June 2022

Key Players in the Technical Textile Market

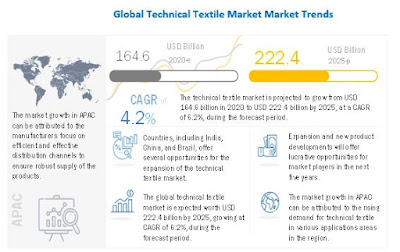

The global technical textile market size is projected to grow from USD 164.6 billion in 2020 to USD 222.4 billion by 2025, at a Compound Annual Growth Rate (CAGR) of 6.2% during the forecast year. The global technical textile market is expanding and is projected to witness high growth over the next five years. Some of the major factors that drive the growth of this market are growing demand for new applications areas and increasing adaptability and awareness of products. The growing awareness about the superior functionality and application of technical textiles encourages the higher consumption of technical textiles and related products.

The technical textile market is led by major players such as Asahi Kasei (Japan), Kimberly Clarke (US), Berry Global Group (US), DuPont (US), Mitsui Chemicals (Japan), and Freudenberg & Co. (Germany). Other players include Low & Bonar (UK), Huntsman (US), Toyobo Co. (Japan), Milliken & Company (US), SRF Limited (India), Koninklijke Ten Cate (Netherlands), and International Textile Group (US). These players have adopted numerous growth strategies to increase their market share, enhance their product portfolio, and expand their market share. Mergers & acquisitions, new product launches, expansions & investments, and agreements & partnerships are some of the major strategies adopted by leading players operating in the technical textile market. The years 2013 and 2020 experienced a large number of investments & expansions by top players in the market.

To know about the assumptions considered for the study download the pdf brochure

Investments & expansions accounted for the largest share of all strategic developments in the technical textile market. Companies such as Berry Global Group, Asahi Kasei, and Freudenberg & Co. adopted this strategy to strengthen their product portfolios, expand their geographic reach, and enhance growth prospects in the technical textile market.

Asahi Kasei (Japan) is a leading manufacturer of apparel material & products, technical textiles & nonwovens, plastic materials, chemicals, and construction materials. Strong global presence and adoption of growth strategies such as investments & expansions and new product launches have ensured its leading position in the market. The company’s technical textiles business deals with a wide range of materials and related products such as cotton, yarns, textiles, and processed products. The group focuses on new product development through research & development activities and innovations. In 2017, Asahi Kasei Fibers & Textiles expanded its capacity to produce Lamous, a high-quality microfiber suede. It is used in a wide variety of applications such as furniture upholstery, automotive interiors, IT accessories, apparel, and industrial materials.

Low & Bonar (UK) is another key player in the technical textile market. The company is engaged in the production of nonwovens for the hygiene, healthcare, geo-synthetics wipes, technical specialties, and building sectors. The company focuses on improving its customer value and expanding in emerging markets by establishing a market-driven product portfolio, upgrading supply chain capabilities, and expanding its presence through acquisitions. For instance, Low & Bonar started its high-performance technical textiles production in Changzhou, to expand its position in the Asian market and become a global leader in the carpet tile backing and automotive markets.

Major market players have adopted diversified strategies for expansion in developed and emerging countries. The Asia Pacific region dominated the technical textile market in 2019. The increase in demand for technical textile can be largely attributed to the growing automobile, medical & healthcare, and construction industries here.

Request for Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=1074

Tuesday 14 June 2022

Blister Packaging Market Driver- Cost-effectiveness

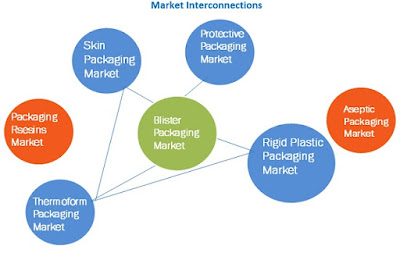

The global blister packaging market size is estimated at USD 24.1 billion in 2020 and is projected to reach USD 34.1 billion by 2025, at a CAGR of 7.2%, between 2020 and 2025. Blister packaging is a transparent, portable packaging material, with a flat base and raised cover of plastic, which is tamper-evident and resistant to moisture, protecting the product from damage. The product to be packed is attached to the base substrate, which could be paperboard, rigid plastic, or aluminum foil. A molded, transparent plastic film is sealed to the base substrate through the heat-sealing process. The transparent plastic film offers high visibility of the product.

To know about the assumptions considered for the study download the pdf brochure

There has been a gradual shift in consumer choice from traditional bottles for pharmaceutical products to blister packaging, which is unit-dose packaging. Blister packs are used in the healthcare industry for drugs and medical devices. They are also used in wide applications in consumer goods, industrial goods, and food industries. Moreover, blister packaging requires fewer resources for packaging, occupy less retail shelf space, and offer an excellent hang-hook display. Hence, blister packs are available at a lower cost as compared to other packaging formats, such as rigid bottles, making them cost-effective.

Emerging economies offer high growth potential to the Blister Packaging Market

Emerging economies such as BRIC (Brazil, Russia, India, and China) and CIVETS (Colombia, Indonesia, Vietnam, Egypt, Turkey, and South Africa) are poised to account for much of the global growth for blister packaging in the upcoming years. Growth in these countries is mainly driven by the favorable demographics, rising household incomes, and changing lifestyles of consumers, encouraging a rising preference for on-the-go products. These factors induce changes in lifestyle that lead to greater demand for convenience in terms of packaging and use.

APAC is the fastest-growing market for blister packaging market

APAC is expected to register the highest CAGR during the forecasted period, owing to the rapid expansion of end-use sectors such as healthcare, food, and consumer & industrial goods sectors. Factors such as rising disposable income, growing middle-class population, rising consumption of high visibility products, and the growing healthcare industry will support the growth of the blister packaging market over the forecast period.

Amcor Plc (Switzerland), DOW (US), WestRock Company (US), Sonoco Products Company (US), Constantia Flexibles (Austrai), Klockner Pentaplast Group (Germany), E.I. du Pont de Nemours and Company (US), Honeywell International Inc. (US), Tekni-Plex (US), and Display Pack (US) are the key players operating in the blister packaging market.

Read More: https://www.marketsandmarkets.com/ResearchInsight/blister-packaging-market.asp

Tuesday 7 June 2022

COVID-19 impact on the Global Aerosol Cans Market

The global aerosol cans market size is projected to grow from USD 10.2 billion in 2021 to USD 12.2 billion by 2026, at a Compound Annual Growth Rate (CAGR) of 3.7% during the forecast year. Aerosol can is a self-dispensing pressurized packaging form, with a permanently attached continuous or metering valve that dispenses the required product formulation in the form of aerosol sprays, streams, gels, foams, lotions or gases, as the contents are introduced and contained in the cans under high pressure and are released with the help of a valve that forces them out through a small orifice.

To know about the assumptions considered for the study download the pdf brochure

The manufacturing of aerosol cans was stopped because of the sudden lockdown imposed in the countries causing the shutdown of manufacturing facilities along with their operations. Expect for healthcare, majority of the aerosol can products fall under the catehorgy of non-essential products except for healthcare. As an implication to this the companies had to stop the production of aerosol cans. Companies shifted their focus to the production of facemasks, sanitizer bottles, and other essential products to recover the losses incurred due to the worldwide pandemic. As the lockdown restrictions were lifted, companies resumed their manufacturing operations. They introduced and initiated the production of small-sized aerosol cans, compared to the average size of the aerosol cans. This change in the idea arised due to the prevalent uncertainty of the pandemic in the minds of the customers. Customers are willingly investing in the same for immediate and short-time use, thus reducing the average can size. The resson being that most of the aerosol cans packaged products fall under the non-essential category.

Beauty spa, saloon, personal care parlor, and others are posing a reduced demand of personal care products. However, the demand has increased at homes. There has been an increase in the usage of personal care products at homes. This has eventually increased the demand for aerosol cans. A similar consumer behaviors has been encountered in the case of users of household care and automotive products, across the world. The leverage of having spare time is enabling people to involve themselves in taking care of their house along with their vehicles by themselves. The third-party service providers are witnessing a decrease in demands for aerosol can packed products in household care and automotive. However, the above described commutative increase in demand for aerosol cans is considerably low to fill the reduced demand gap which has arised due to the pandemic. Healthcare aerosol can products are included into the essential products category, and hence, their demand has been witnessing an increase, as compared to the other aerosol can products (such as personal care, household, and automotive).

APAC is the fastest-growing market for aerosol cans market.

APAC is projected to be the fastest growing market for aerosol cans during the forecast period and is projected to register the highest CAGR among all the regions. The growth in aerosol cans market in APAC region is attributed to increasing disposable income in the developing economies such as China and India. Key factors such as industrialization, growth of the convenience food industry, rise in manufacturing activities, increase in disposable income, rise in consumption level, and the growth in retail sales have contributed to the growth of the aerosol cans market during the forecast period in the region. Moreover, the spending on packed food and beauty care has increased, which is driving the demand for aerosol cans in the region.

Ball Corporation (US), Trivium Packaging (US), Crown (US), Mauser Packaging Solutions (US), Toyo Seikan Co. Ltd. (Japan), Nampak Ltd. (South Africa) CCL Container (US), Colep (Portugal), CPMC Holdings Ltd. (China), Guangdong Sihai Iron-Printing and Tin-Making Co.,Ltd. (China), and others are the key players operating in the aerosol cans market.

Request for Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=48885732

DS Smith (UK), Smurfit Kappa (Ireland) and CCL Industries Inc. (Canada) are leading players in Digital Printing Packaging Market

The global digital printing packaging market size is projected to grow from USD 29.4 billion in 2022 to USD 45.1 billion by 2027, at a CAGR...

-

Crown Holding (US) and Amcor (Australia) are the Key Players in the Plastic Caps and Closures MarketMarketsandMarkets projects that the plastic caps and closures market size will grow from USD 40.52 Billion in 2018 to USD 51.67 Billion ...

-

The report “ Inventory Tags Market by Technology (Barcodes, RFID), Label Type (Plastic, Paper, Metal), Printing technology (Digital ...

-

The global self-adhesive labels market size is projected to grow from USD 47.9 billion in 2021 to USD 62.3 billion by 2026, at a CAGR of 5...